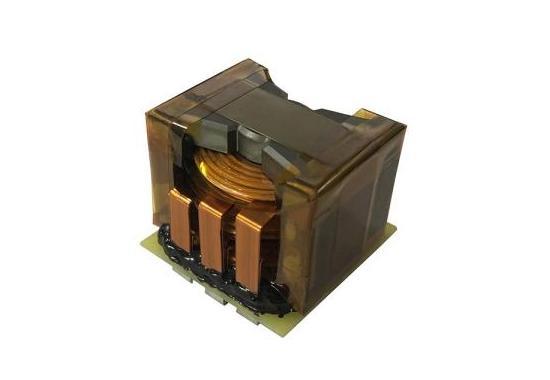

A planar transformer uses flat windings that can be placed directly on a PCB. It is precisely the use of a PCB with tracks to the shape of the windings window that creates the planar form factor. The main advantages can be summarized as follows:

Low profile. It allows for a small, elegant design.

Efficient heat management. The profile means more surface area, allowing the transformer to dissipate more heat.

Repeatability: consistent performance without the variation in parameters such as leakage inductance seen with wire wound devices.

Planar magnetic cores provide better thermal characteristics for heat conduction and keeping the device at lower temperatures than with wire-wound equivalents. Planar magnetic cores, which have a higher surface-area-to-volume ratio than conventional ones and which more effectively exchange heat with the environment, enable this.

As with all designs, there are compromises to be made when integrating a planar transformer into the board layout. In particular, traces are used as windings, so the current and thus the dissipation must be kept in mind. High temperatures imply more space on the board. That is, different requirements in terms of track width can limit the turns. This all depends on the overall size of the power supply under construction. A planar transformer requires the component to undergo a standard PCB manufacturing process.

The planar transformer is a component that may be incorporated or used alone. The appropriate dielectric thickness between the board’s multiple layers is one thing to keep in mind. The maximum voltage (due to breakdown) and the rate of heat dissipation are all dependent on the dielectric material used. It also influences the leakage flux between the windings. Additionally, interwinding capacitance must be limited to reduce capacitive losses between the windings or between the planes near the transformer coils. Thus, the useful frequency is limited by capacitive coupling.

Planar magnets have the benefit of lowering the height of transformers. In addition, because multilayer boards are costly, a planar transformer is often made and added to the board rather than being included in the board itself (as is the case with some DC-DC planar devices).

Planar transformers are often made using PCBs or copper foil windings with low-profile magnetic cores. Even though PCB windings offer significant industrialization advantages (manufacturability, cost savings, repeatability), it is challenging and requires specialized tools, technology, and engineers’ time to create multilayer PCB transformer prototypes. Planar component prototypes are thus expensive, are challenging to develop, and often require specialist subcontracting.

Planar transformers provide a good solution for high-frequency switching-mode power supplies. The usage of these types of transformers has increased recently because of their benefits of reduced size.

Dongguan Fengxie Electronics Co., Ltd 2025 © All rights reserved. ICP:粤ICP备2023034420号